Improving Maritime Safety on a Budget

Sep 24, 2015 Murray Goldberg 0 maritime safety, Maritime TrainingThe following post was originally written by Murray Goldberg for Maritime Professional as a part of a series of articles called The Human Element on a Budget. To celebrate World Maritime Day’s theme of education and training, we are re-posting the article here to help give vessel operators more ideas on how to improve their training.

There are many ways for a maritime organization to improve their training, performance and safety culture. However, not every vessel operator has the size or resources to create a wholesale transformation in training and safety culture. Many smaller organizations often want to improve their training, but feel that they do not have the resources to do so. Fortunately, it’s possible for organizations of any size and resources availability to greatly improve how they train regardless of their budget. No budget is too small, and the benefits to the organization in terms of safety, performance, and culture will always outweigh the cost and effort expended. The costs involved can often even be done with the funds already devoted to training. I have seen such “transformations on a budget” many times in other industries over my time in educational technology.

The purpose of this series of blog posts is to talk about how we can improve in-house training outcomes and an organization’s maritime safety culture on a budget. There are lessons we can take both from within and outside the maritime industry, and there are new tools that can be used to economically transform your organization. It does not take a lot of financial resources, but it does take a genuine desire to improve, and buy-in from top management. The only sure way of failing is to not try.

In this first article, I will present a small case study on how a small company that transformed their safety and training with very modest resources. In the subsequent posts, I will give concrete lessons and tips learned from this small company’s experience.

The Overall Strategy

It is often the case that organizations do not engage in a process of safety and culture improvement because they are under the mistaken impression that there is no use. The costs are simply too high for an organization of their size, and therefore there is no point in trying.

It is certainly true that, all else being equal, a large budget can help yield results more quickly than a small budget. However, with some planning, great results can also be achieved on a small budget. It may very well be the case that some re-allocations of the existing training budget can result in safety improvements. This is a scenario that is repeated with success in all industries. In fact, if you think about companies which have strong safety and training cultures, you’ll see that their success was not achieved through large one-time efforts. It is achieved through a continuous process that is built into the daily operations of the company. The good news is that the cost can be kept small and spread over the lifetime of your company.

The overall strategy for transforming your maritime safety performance and culture on a budget is to start small and plan for continued incremental growth and improvement.

Even though the timeline for your initiatives will be longer, there will be visible and concrete results in the near term, and these will quickly influence the training and safety culture within your organization. By doing a little planning, starting modestly, and then growing incrementally as time progresses, the cost and commitment are small, but the ultimate reward is huge. As I said above, you can’t fix everything all at once. But if you want to succeed, you need to start sometime. All it takes is a decision to begin. If not now, then when?

A Small Case Study

When I was working in my first company, WebCT, we had a customer in the manufacturing sector. They were a small organization with approximately 100 employees. They had grown to that number over a period of about 10 years, and had come to the realization that even though they were still relatively small, they were employing the same training practices they had used when they had only 10 or 15 employees. They had more or less moved along by momentum, changing practices only when they were forced to by their customers, their union, or some other unavoidable requirement. It was not as though they were not making sure that training happened – they did. But they had no strategy around training, and so rather than continuously improve, they were on an unpredictable path which sometimes meant training improved, and other times meant it suffered. Most importantly, they really could not say for sure how successful their training was, because they never took the time to measure it. They were generally doing fine, but their days lost due to accidents were on the rise. So they finally decided they had better do something before the lack of attention to training finally caught up to them in an expensive or tragic way.

The company decided to take a fairly intelligent, yet modest, approach. They gave themselves three months to formulate an initial plan. They wanted the plan to address four goals:

1. First, the plan and its initiatives needed be achievable within the currently available resources and budget.

They did not have any additional resources they could throw at this.

2. Second, they decided that the plan had to define how the plan itself was managed.

This was meant to ensure the plan had a future, and not just a present. Therefore, the plan included guidelines for how often the plan would be reviewed, who would be in charge of the plan, who would participate in formulating and executing the plan, how the plan would be communicated, how success would be measured, and how the plan would be improved. Although this may sound like a lot of effort, in truth it was very little because none of these components of the plan were spelled out in any great detail – and they did not need to be. Some parts were little more than position statements requiring that these issues needed to be addressed, and requiring that they be addressed in a reasonable amount of time.

3. Third, the plan needed to define and implement the infrastructure for long-term success.

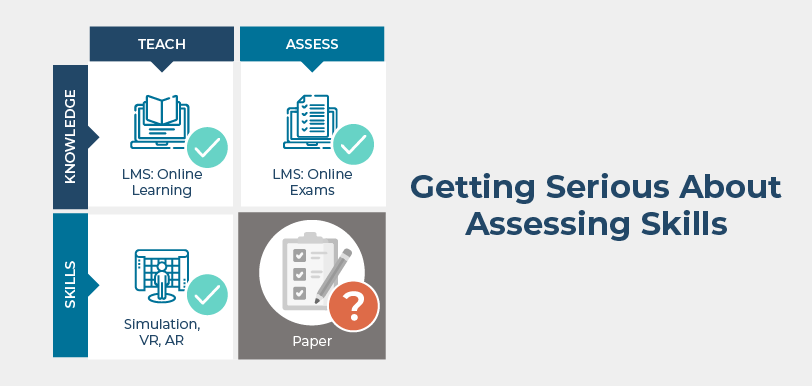

For them, the infrastructure for success meant choosing a learning management system (LMS) which could deliver their new training initiatives, reduce their training costs, provide training metrics and analytics so they could see how successful their training was, and grow with them as their needs grew. As I mentioned, they were customers of my last company, so they had chosen WebCT to use as their LMS (which is how I came to work with them). WebCT fit the bill because it was relatively inexpensive for an organization of their size (about $250 per month), yet provided all the required metrics so they could measure success. Equally importantly, it would grow with them to support any amount of training or any company growth.

4. Finally, the plan had to define one short-term meaningful project that improved training outcomes and/or reduced costs.

They decided this initial project must be achievable in, at most, 6 months. The project did not have to be grand or expensive, just useful and visible. It was a way for them to put their plan and infrastructure to the test and to demonstrate their commitment to transforming training in the company. As I recall, they later decided that this first project would be to take their new hire training and make it available on-line using their new LMS. This was a modest project and the costs were fully recovered because they were able to reduce the time (and therefore the employee costs) for new-hire training. It also allowed them to start gathering metrics on training they had been doing for a long time – enabling them to get comfortable with the LMS and cut their teeth on the new approach using familiar material.

The most important aspect of all this was not in the details of their particular approach, but was in their decision to get going. Once they made that decision, they made the transition from a company which was relatively static in terms of its training methods and outcomes, to one which started down the path of continuous improvement.

I was involved with that customer for several years and they really did change as a company. They revisited, refined and improved their plan every year. They also decided that they would accomplish one new training initiative every 12 months – which ended up being the cycle on which they would revisit and refine their plan. To that end, they implemented a program of continuous improvement – annually measuring their training performance and making changes to improve. In addition to measurably improving their training and reducing days lost due to accidents, they felt as though morale in the organization was better, and that even the union/management relationship improved as a result of their commitment to training and safety – even though the cost and effort was very modest.

The takeaway

The hardest step in any journey is often the first one, because it may seem like a large step. But it does not have to be. Instead, start small – but start somewhere. You do not need to know all the details at the beginning. Just get the ball rolling and the details will fall into place as a result of the process you’ll be undertaking. The first step for small organizations is typically little more than the decision to begin the journey with a commitment to formulate a plan. At the beginning, even the plan can be modest because it will be refined and improved with time.

Thanks so much for reading and have a wonderful day!

Blog Notifications:

For notifications of new maritime training articles, please follow this blog.

Interested in Marine Learning Systems?

Contact us here to learn how you can upgrade your training delivery and management process to achieve superior safety and crew performance.