Maritime Safety Culture: An Interview with Captain John Wright

Mar 9, 2016 Murray Goldberg 0 Interview, maritime safety, Safety CultureIntroduction

This is the second in a series of articles on Safety Culture in the maritime industry. As mentioned in the first article, “Safety Culture” is one of those terms that is used a lot in the maritime industry. But how many of us can define it, and how do we know if we have it?

The last blog post gave an overview of maritime safety culture. It provided a basic definition and discussed the importance:

- management leadership,

- training,

- measurement,

- a focus on learning rather than blame,

- and continuous reflection

had on a culture of safety. The article then concluded by introducing Captain John Wright, an award-winning maritime safety culture expert. This blog post continues the discussion with Captain Wright.

Talking with the Expert

I had the very good fortune of meeting Captain Wright because of his involvement with the BC Ferries SailSafe project – a multi-phased project aimed at improving safety (and one that the company I work for, Marine Learning Systems, is fortunate and proud to be a part of). Through SailSafe, BC Ferries has seen time loss injuries cut in half, serious injuries reduced by two-thirds, and annual insurance claims costs reduced by over three-quarters. And the numbers continue to improve.

It’s clear that Captain John Wright is someone who understands safety culture. Captain Wright is a Master Mariner and has spent his long career in the maritime industry in a variety of roles including those of vessel master, marine superintendent, chief executive and general manager. All of John’s roles have had a focus on safety and cultural change. He holds a wide variety of certificates and qualifications concerning health and safety, risk management and safety technology.

Captain Wright developed an early passion for safety and culture after experiencing, first hand, the aftermaths of fatal accidents on drilling rigs in the North Sea. Those experiences and his qualifications compelled John to create WrightWay Training Limited – a company delivering management safety consultancy and training services worldwide since 1996.

In June, 2013, John was honored with the IHS Safety at Sea Award for training. This award recognises innovation and excellence in the maritime safety industry. WrightWay was selected for its ‘Securing the Future’ culture change programme and its Human Element Leadership & Management (HELM) training. The two combine to provide a workforce empowering process that creates a ‘one team’ approach to safety across a company. Judges of the award said:

“WrightWay has demonstrated its advanced approach to maritime safety through creating a culture of shared ownership and accountability, which results in fewer injuries, a safer and healthier working environment, a happier workforce and greater profits.”

It is for these reasons that we are speaking with John Wright today. Let’s move to our interview with Capt. Wright:

Q: What is the secret to safety and loss avoidance?

“Put simply it’s real workforce involvement. It is necessary to close the ‘chasm’ that often exists between the front line workers and their managers and directors and create a ‘one team’ environment. This is achieved by running the business such that the health, safety and welfare of the employees are put first, second and last by the leadership team – genuinely and transparently. Inhabiting this morally invulnerable high ground satisfies the hugely important human need in the employees of being valued and listened to. When this trust is built there is absolutely nothing better an organisation can do to improve all aspects of its business.

One company achieved a 3 to 1 return on investment and I know of no other way that’s possible to achieve! Better still, everyone goes home in one piece to their loved ones!”

Q: For management, what is the biggest indicator that they can look for in their company to determine whether they have a safety culture problem — before an accident occurs?

“This is a big question. The best indicators are the clues presented by the five-stage safety culture maturity level model, as identified in UK Health & Safety Executive research first published in 2001.

- Stage 1 ‘Emerging’;

- Stage 2 ‘Managing’;

- Stage 3 ‘Involving’;

- Stage 4 ‘Cooperating’;

- and the final Stage 5 ‘Continually Improving’.

There are quite a few indicators that identify which stage a company has reached and they are too numerous to list here. The most important of all is how well accidents, incidents, near misses (which we prefer to call ‘learning events’) and first aid cases are reported, acted upon and learned from. Under-reporting is common, especially on the leading indicators, in safety cultures up to and including level 3. The problem is often denied or not recognized, but is a solid reliable indicator.

Another, is how often directors, managers and front-line supervisors visit their people at their place of work and how well they communicate with them. Is the communication conducted in a, ‘I speak, you listen’ way, or is it a conversation seeking the employees ideas on what’s wrong and how he/she thinks it can be fixed (which by the way they always know? The quality of these conversations is critical and yet managers are rarely given any help with developing these skills, which once again will not occur spontaneously.

Another clue to the culture is when training is the first thing to be cut when business is poor – it should be the absolute last thing that is axed.”

Q: If management is fully behind culture change, how likely is it to succeed?

“Very. However, since as we know it takes time to achieve, the quality of the leadership team’s ability to press on with the process in the face of there being no apparent early signs of change, together with other pressures weighing in on them, cannot be overestimated. The CEO especially has to have courage and lead the process from the front. The management of change is notoriously difficult but the fruits of this labour are inestimable.”

Q: If you had to say, what is the one most important ingredient in culture change?

“The quality of leadership from the top: The knowledge and commitment from the leadership team, their abilities as leaders to inspire their people and demonstrate their belief in the process, and prove by their actions to the most complete cynic in the workforce that they are genuinely putting the health, safety and welfare of their people as their number one priority.”

Q: Is culture change always top down? Where does it start and who is involved as it progresses?

“Only in as much as the demonstrated evidence of Board level commitment I have just described. Thereafter, and when belief begins to spread in the workforce, it is very much bottom up driven, with processes owned and executed by the workforce.”

Q: What is the biggest challenge to a positive culture change?

“The ‘engine room’ of any organisation is without doubt its middle management level people. In shipping these are the superintendents ashore and the captains and chief engineers on the ships. So, once the Board of Directors are committed to the process (which is usually a relatively straightforward process) and the front line employees begin to recognise what is being attempted (and they dare to hope, which is also relatively quick to happen for the majority), then the main challenge is to convince these critical middle management employees of the need for this process and the need for them to change.

They need to change from the ‘I speak, you listen’ command and control style of management, to the ‘How can I help you and how can I support you?’ method. They also need to be comfortable and empowered to ask their boss for help and support. All of this does not occur spontaneously, or by a process of osmosis! Leadership & Management training is essential and this is where the STCW 2010 mandated Human Element Leadership & Management (HELM) training becomes essential.”

Q: How do the attitudes and behaviors of individuals relate to safety and culture change?

“This question encompasses why culture change is a 5 to 10 year ‘voyage’. The ‘battleground’ is to change the collective attitudes, beliefs and values of the employees, since it is they that drive behaviours. This takes time, as realisation dawns in the minds of employees that the company is serious about the process and that this initiative will not just be a passing ‘flavour of the month’.

Once this occurs, usually after about a year or so, then eventually the 80 / 20 rule kicks in and 80% of the committed employees drag most of the other 20% along, as they don’t wish to be the odd men (or women) out. In many cases the few remaining disenfranchised will leave. It is usual to expect that when people who are influencers in the company (and may often be early cynics) embrace the necessary changes of behaviour, they carry many others with him.”

Q: Aside from attitudes, what are the most important factors of the human element that most companies need to address?

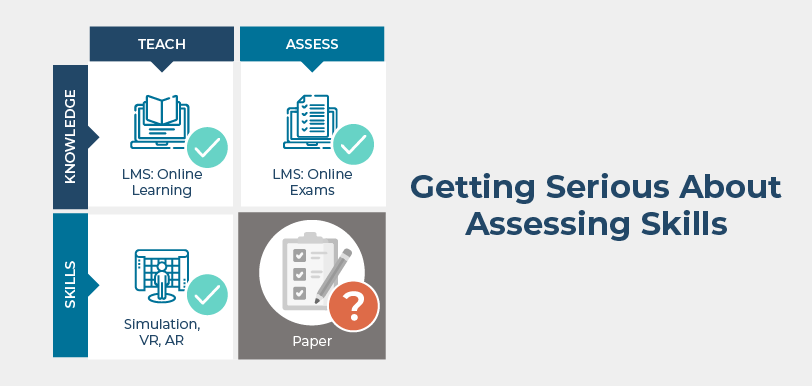

“The first is standards of competence and the training needed to ensure those competencies. This includes especially (but not exclusively) human factor, leadership & management skills. All training needs to be validated, that is, it must be proven to be delivering at the sharp end and not just recorded in a tick box, which is so common and means nothing.

The second is to ensure Standard Operating and Emergency Procedures are introduced and above all owned by the end users. This means real workforce involvement in their construction, who in turn will ensure they are simple, brief, relevant, updated and vessel / work area specific. The same workforce involvement needs to be embraced in areas such as the management of maintenance, design, choice of equipment purchased, ensuring effective closed loop communications, decision-making & a useful modern 360 appraisal system.”

Q: Is safety and culture change expensive?

“The answer to this question is that oft quoted saying, “If you think safety is expensive, try an accident!”

One company found nearly $40M in savings from the process over a five year period and another turned a derisory $7.5 M profit on a huge turnover into $150M over a seven year period. There is nothing a company can do that is more productive, and more importantly, everyone goes home to their loved ones in one piece: Money can’t buy that level of job satisfaction!”

Conclusion

There are many important takeaways from our interview with Captain Wright. However for me, the most important messages are that:

- Culture change takes time, but it is achievable.

- It requires that we expose errors and turn them into learning opportunities.

- It requires real leadership (and participation) to make it happen.

- It not only saves lives and prevents injuries, but it can be exceptionally good for the bottom line.

If you are not sold on the importance and accessibility of safety culture transformation, visit a vessel operator that has successfully undergone one. There is no better way to understand how powerful it can be. Most that have already undergone such a transformation will be very willing to receive you and tell their story – that’s just part of the culture. You will find the visit very compelling – I guarantee it.

A special thank you to Captain Wright for sharing his thoughts here. If you would like to reach Captain Wright, you will find his contact information on his website.

Thanks for reading and sail safe!

Follow this Blog!

Receive email notifications whenever a new maritime training article is posted. Enter your email address below:

Interested in Marine Learning Systems?

Contact us here to learn how you can upgrade your training delivery and management process to achieve superior safety and crew performance.